Views: 66 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

Technical Exploration: Nonlinear Nature and Theoretical Evolution of Disc Spring Characteristic Curve

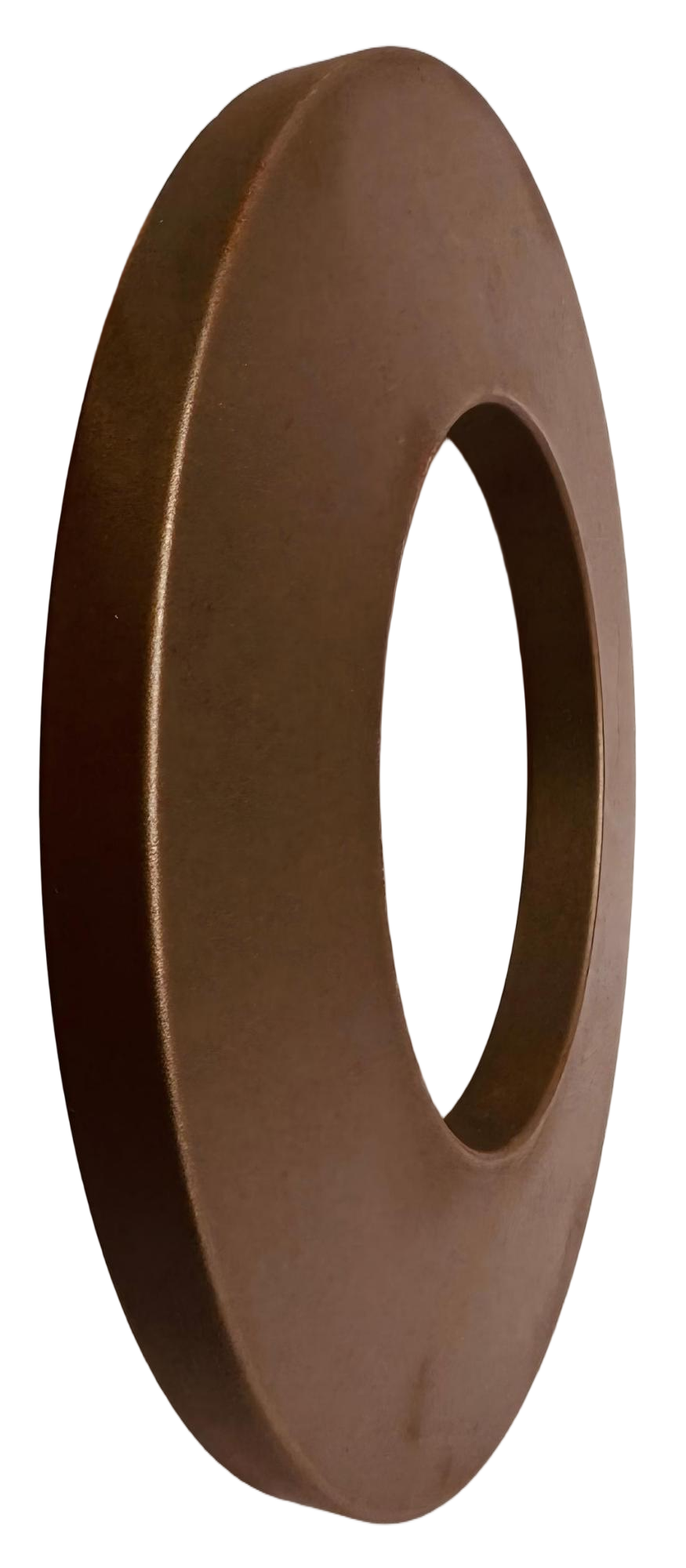

In the field of elastic mechanics, many classical theoretical formulas exhibit linear relationships, whereas disc springs demonstrate pronounced nonlinear force-displacement characteristics. This behavior stems from their unique geometric configuration and precise mechanical description. Jiangsu Sunzo Spring will analyze the fundamental nature of disc spring nonlinearity and the evolution of its theoretical models, building upon the technical foundations of disc spring technology.

In fact, in the early theoretical studies (such as the work of Timoshenko, Liu Hongwen, etc.), there were also linear disc spring theoretical formulas. These formulas were based on the following simplifications:

The relationship between stress and strain is a linear function of the section angle.

Mechanical model: the initial configuration is used for calculation, and the geometric changes during deformation are not considered.

Application scope: This linear formula is only applicable to small deformation, and the error is significant when the deformation is large.

To achieve engineering-grade accuracy, the Almanrazro (AL) formula employs a more rigorous mechanical description.

1. The stress-strain relation: the second order term of the angle is considered, which can describe the response of the material more accurately under large deformation.

2. Geometric nonlinearity: The calculation of the lever arm adopts the updated configuration, which considers the change of the actual geometric position after the deformation of the disc spring, and this item itself is a function of the angle.

3. Mathematical synthesis: When the second order stress-strain relation is multiplied by the first order geometric change term, the force value of the disc spring is naturally deduced as the third order function of the section rotation angle.

The nonlinear relation of the third order accurately describes the mechanical behavior of the disc spring in the large deformation range, including:

Potential negative stiffness interval (when h₀/t> √2)

Different stiffness characteristics such as decreasing and increasing stiffness

better agreement with the actual test data

This theoretical rigor makes the AL formula the foundation for engineering calculations in both China's GB/T 1972' Disc Spring Standard' and international standards.

At Jiangsu Sunzo Spring, we possess a profound understanding of the theoretical model of disc springs:

Model selection: We select appropriate computational models based on specific application scenarios (e.g., deformation scale and precision requirements).

Design verification: In the design of disc spring, we not only apply the standard formula, but also understand the mechanical principle behind it, which provides theoretical support for the design under special working conditions.

Innovation foundation: Through in-depth understanding of nonlinear characteristics, we can better design disc springs with specific stiffness curves to meet customers' customized requirements.

We believe that profound theoretical understanding forms the cornerstone of exceptional engineering practice. By mastering the full spectrum of theoretical tools—from linear simplifications to precise nonlinear models—we can deliver disc spring solutions with more accurate performance predictions and more rational designs for our clients.