Views: 59 Author: Site Editor Publish Time: 2025-04-25 Origin: Site

The Secret Behind an Elevator's "Steadfast As Mount Tai" Performance: The Hardcore Role of a Disc Spring

Industry Background

Elevators, as indispensable vertical transportation tools in modern architecture, place paramount importance on safety, stability, and comfort. The Sanzhong elastic disc spring, with its unique characteristics of high stiffness and compact design, has become an ideal choice for elevator braking, buffering, and door locking systems.

Technical Key Points

1. High stiffness with vibration damping capacity: Disc springs can withstand heavy loads within small deformation ranges, making them suitable for space-constrained elevator brakes and buffer devices.

2. Variable stiffness characteristics: The variable stiffness properties of disc springs enable effective absorption of impact energy in elevator buffer systems, protecting both elevator structures and passenger safety.

3. High fatigue life: Manufactured from high-strength steel with specialized heat treatment, disc springs exhibit superior fatigue resistance to meet the long-term operational demands of elevators.

Application Principle

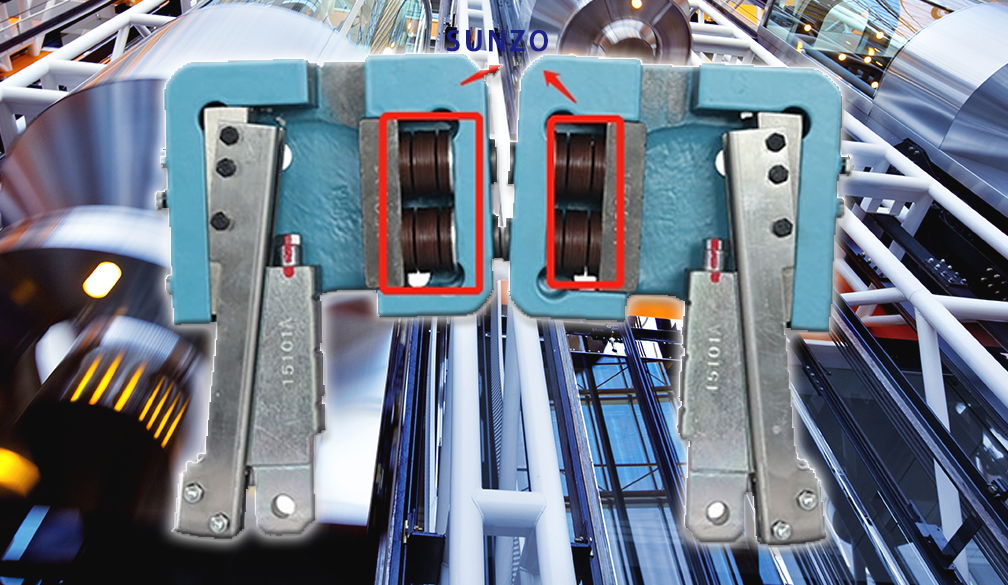

1. Elevator Braking System

Disc springs provide stable preload force in elevator brakes through their high stiffness characteristics, ensuring reliable operation under high-temperature and high-load conditions. When the brake is activated, the disc springs rapidly release stored potential energy to achieve quick braking.

2. Elevator Buffer Device

In the bottom buffer device of elevators, disc springs utilize their variable stiffness characteristics to effectively absorb impact energy, reducing vibration and noise when the car hits the bottom. By optimizing geometric parameters of disc springs (such as thickness and number of layers), precise control over the buffering force can be achieved.

3. Elevator Door Lock Mechanism

Disc springs are used in door lock mechanisms to provide stable locking force, ensuring the safety of elevator doors under various working conditions. By accurately calculating the preload force and deformation of disc springs, it is possible to ensure quick release of the door lock in emergency situations.

Solution

1. Customized Design

Provide tailored designs for disc springs based on specific elevator requirements, including dimensions, materials, and performance parameters. Feasibility and reliability of the design are ensured through finite element analysis and experimental validation.

2. Installation and Maintenance

Offer detailed installation guidance and maintenance recommendations, including preload setting for springs, deformation monitoring, and periodic inspection methods, to ensure long-term stable operation of the product in elevator systems.

3. Quality Assurance

Strictly adhere to international standards (such as ISO 9001, IATF 16949) and industry specifications to guarantee product quality. High-quality elastic components are delivered through material testing, manufacturing process control, and finished product inspection.

4. After-Sales Service

Provide technical support and after-sales services to assist customers in resolving usage issues and extending product lifespan, including fault diagnosis, performance optimization, and replacement recommendations.

Conclusion

With its unique characteristics, Sunzo's disc springs provide an efficient, reliable, and safe elastic component solution for the elevator industry. Through technological innovation and customized design, we are committed to supporting the sustainable development of the elevator industry.