Views: 48 Author: Site Editor Publish Time: 2025-06-26 Origin: Site

Parametric Selection Analysis of Disc Spring Series A/B/C (Based on GB/T 1972-2023)

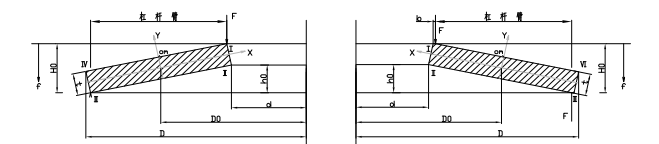

The series differences of disc springs are determined by geometric parameters and stiffness characteristics, with their mechanical behavior described by the following models:

I. Core Parameters and Stiffness Characteristics

Stiffness formula:

![]()

![]()

(E: Elastic modulus, μ: Poisson's ratio, α, β: Geometric correction factors)

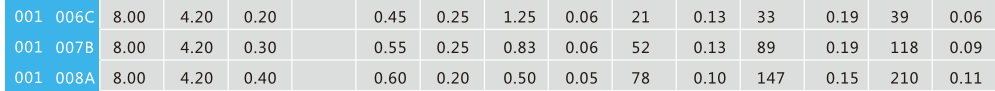

Series | ho/t | De/t | Stiffness Range(N/mm) | Extreme deformation Slim |

A | 0.4 | 18 | 500-2000 | 0.75ho |

B | 0.75 | 28 | 200-800 | 0.80ho |

C | 1.3 | 40 | 50-200 | 0.85ho |

Note: Series A offers medium stiffness with strong versatility; Series B reduces stiffness by 32% but increases deformation capacity by 40%, making it suitable for buffering; Series C exhibits stiffness reduced to 10% of Series A, specifically designed for large deformation scenarios.

II. Load Characteristics and Nonlinear Correction

Load-displacement relationship

![]()

(K: Nonlinear coefficient, with values of 0.65/0.82/1.12 for Series A/B/C respectively)

III. Guidelines for Combined Applications

1. Stiffness adjustment:

- Stacked group stiffness: K_total = n K

- Opposed group travel: S_total = n s

2. Hybrid design constraints:

![]()

IV. Selection Strategy and Standard Coverage

- Versatility ranking: A > B > C (Priority given to Series A);

- Standard differences: GB/T 1972-2023 does not fully cover DIN 2093 parameters, requiring reference to German standards for special conditions.

Conclusion: Selection requires collaborative analysis of stiffness K, ultimate deformation Slim, and nonlinear factor K. For complex working conditions, FEA verification is recommended to ensure Omax ≤ 0.7Os (yield strength).