Views: 147 Author: Site Editor Publish Time: 2025-03-28 Origin: Site

In the field of rail transit, the reliability of the braking system directly affects the operational efficiency of trains and the safety of passengers. As a key elastic component of the braking system, disc springs are subjected to high-temperature creep and complex service environments (such as marine climates, low-temperature conditions), making their performance stability crucial. Jiangsu Sunzo Elastic Technology Co., Ltd. (hereinafter referred to as Sunzo Elasticity), leveraging advanced material heat treatment processes and surface corrosion-resistant technologies, offers long-life, high-corrosion-resistant disc spring solutions to global rail transit clients, aiding in the safe and stable operation of rail transit braking systems.

Industry Challenges: Disc Springs in the Rigorous Conditions of Rail Transit

Rail transit disc springs face multiple challenges during their service life:

High-Temperature Creep: During the braking process of high-speed trains/subways, the temperature of the braking system can reach over 700°C. Prolonged high-temperature environments can lead to high-temperature creep in disc springs, affecting braking effectiveness.

Corrosion Risk: High-speed trains operating in marine climates or in cold environments requiring NaCl de-icing can accelerate the rusting of disc springs, thereby reducing their performance.

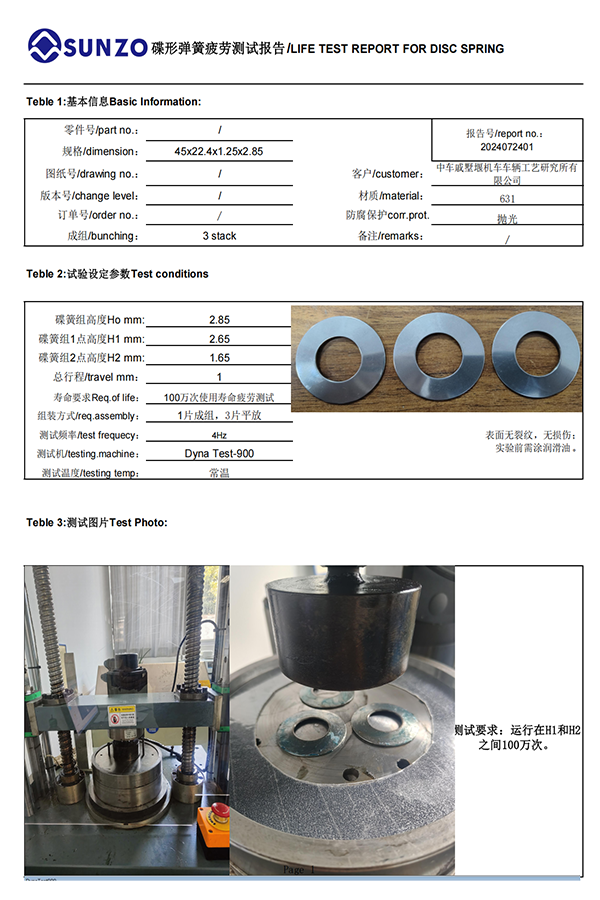

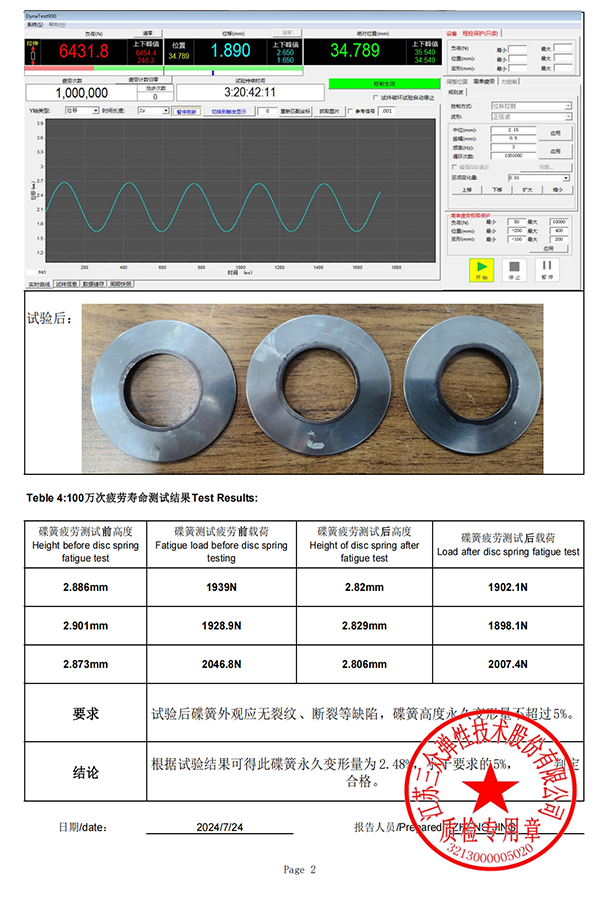

Fatigue Failure: High-frequency braking during the operation of high-speed trains/subways is a dynamic load for disc springs, requiring them to have a high fatigue life, typically reaching 1 million cycles.

If the performance of the disc springs cannot meet these requirements, it may lead to delayed braking or even safety hazards, thus imposing extremely high demands on the raw materials and design of the disc springs.

Sunzo Solutions: Comprehensive Breakthroughs in Materials + Processes + Design

To address the above industry pain points, Sunzo has created high-performance disc spring products for rail transit through optimization of raw materials and heat treatment processes, and innovation in surface treatment:

1. Raw Material Optimization

(1) High-performance stainless steel is used instead of traditional spring steel to enhance the corrosion resistance of the disc springs.

(2) The alloy composition and its proportion in stainless steel are optimized to improve the corrosion resistance of the disc springs.

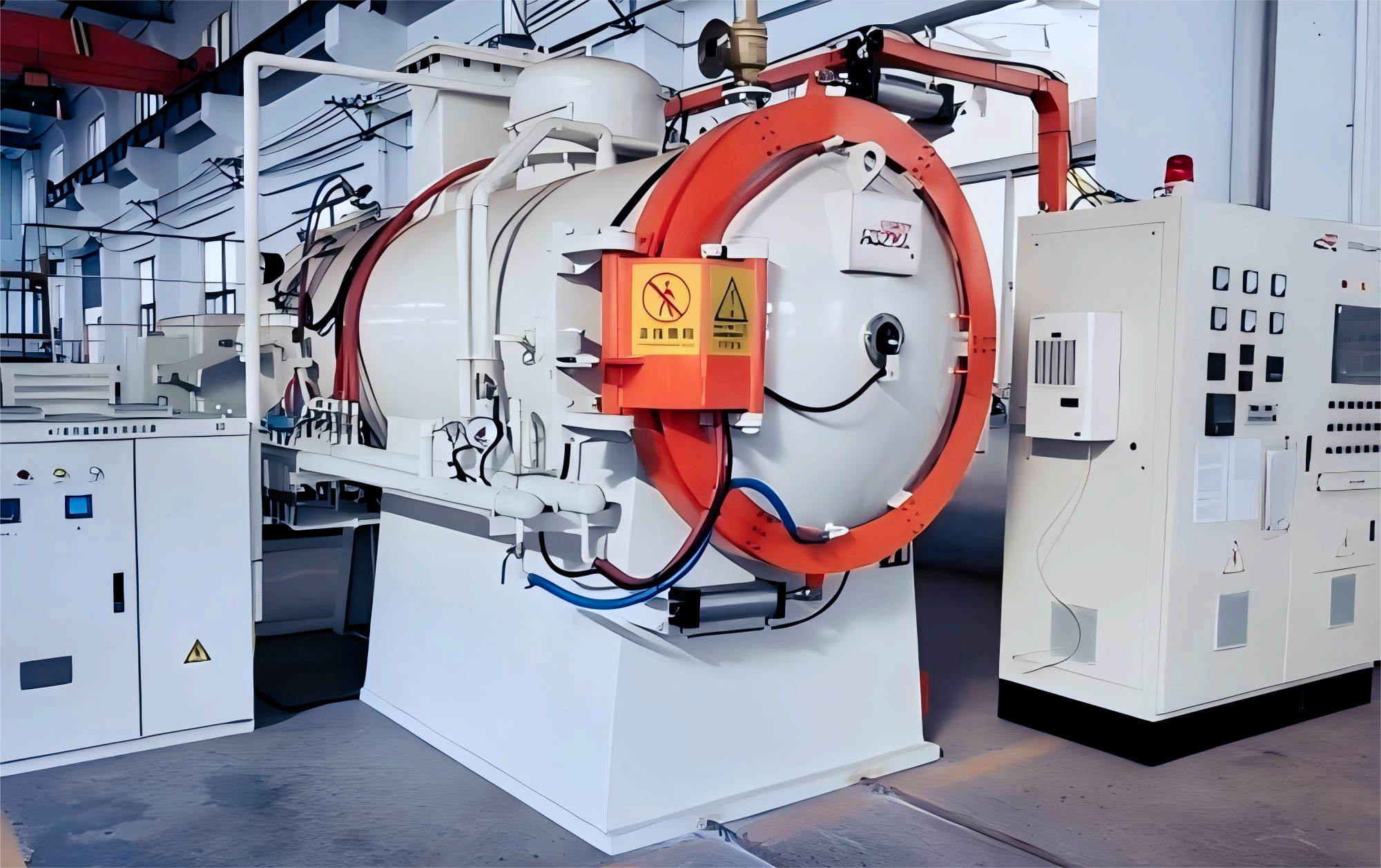

2. Heat Treatment Process Optimization

(1) The solid solution temperature and aging temperature are optimized to control the precipitation of carbides, achieving the purpose of resistance to pitting corrosion.

(2) By controlling the number and size of carbide precipitates, the high-temperature creep resistance of the disc springs is improved.

3. Surface Treatment Technology Innovation

(1) Through innovation in surface treatment processes, general corrosion of the disc springs is suppressed.

(2) Disc springs manufactured with this process have undergone a 168-hour durability test in 5% NaCl neutral salt spray without corrosion.

Core Performance Indicators:

Fatigue Life: Fatigue test ≥ 1 million cycles.

Corrosion Resistance: Salt spray test ≥ 168 hours.

Creep Resistance: High attenuation ≤ 0.02mm.

Success Cases: Serving Global Top Clients

Sunzo disc springs have been widely applied to rail transit projects both domestically and internationally, with cooperation clients including:

Knorr-Bremse: Supplying high-precision disc springs for high-speed train braking systems, certified by the EU TSI.

CRRC: Supplying urban rail vehicle braking components, aiding in the localization substitution.

Purun Braking: Supplying core braking components for high-speed trains, promoting breakthroughs in independent technology.

Protecting Rail Transit Safety with Technology

Sunzo Elasticity has always been deeply engaged in the field of elastic components, solving industry development pain points through continuous technological innovation. In the future, we will continue to partner with high-quality enterprises in the industrial chain to promote the high-quality development of global rail transit equipment!

For more technical details or customized solutions, please feel free to contact us!