Views: 101 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

Jiangsu Sunzo Spring Technology Co., Ltd. has a production and manufacturing department consisting of 3 workshops and 9 teams. Among the teams, there are over 40 homo sapiens with intermediate or higher technical skills. The entire production team members are highly educated, relatively young, and possess strong execution capabilities, along with excellent work competence, innovation ability, and team spirit.

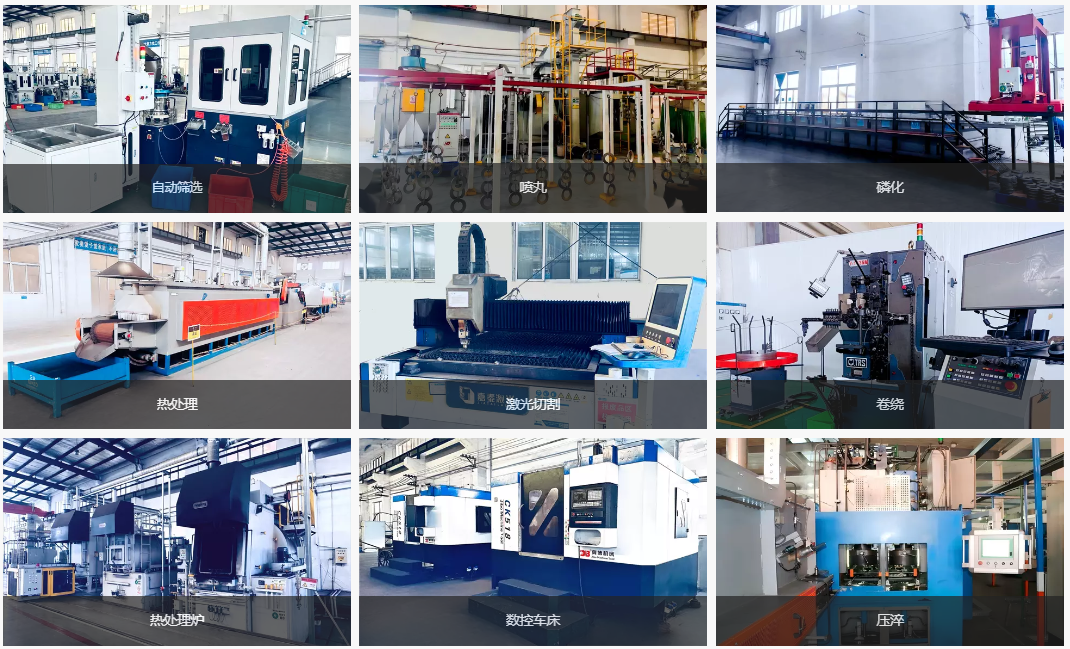

Production Equipment

Testing Equipment

The workshop is equipped with over a hundred various production facilities including shearing machines, water jet cutters, punching presses, lathes, machining centers, drilling machines, wire cutting machines, shot blasting machines, surface treatment equipment, resistance furnaces, and automatic high-pressure presses. It also possesses more than 40 medium-to-large-scale testing instruments such as hardness testers, pressure testing machines, tension gauges, spectrometers, metallographic microscopes, salt spray test chambers, and sample preparation machines. The workshop has a daily production capacity exceeding 30,000 pieces (PCS) of elastic components.

Manufacturing process

The workshop adopts German enterprise management models, strictly focusing on the 5M1E key points—"homo sapiens, machine, material, method, measurement, environment"—six essential elements. It integrates 5S on-site management and ERP software applications to cover a comprehensive series of processes from material handling to stamping, turning, forming, heat treatment, compression, surface treatment, inspection, and packaging. Through efficient quality control measures, material waste is minimized, and quality efficiency is enhanced. The workshop operates in a standardized and highly efficient manner, capable of promptly meeting various customer order demands.