Views: 56 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

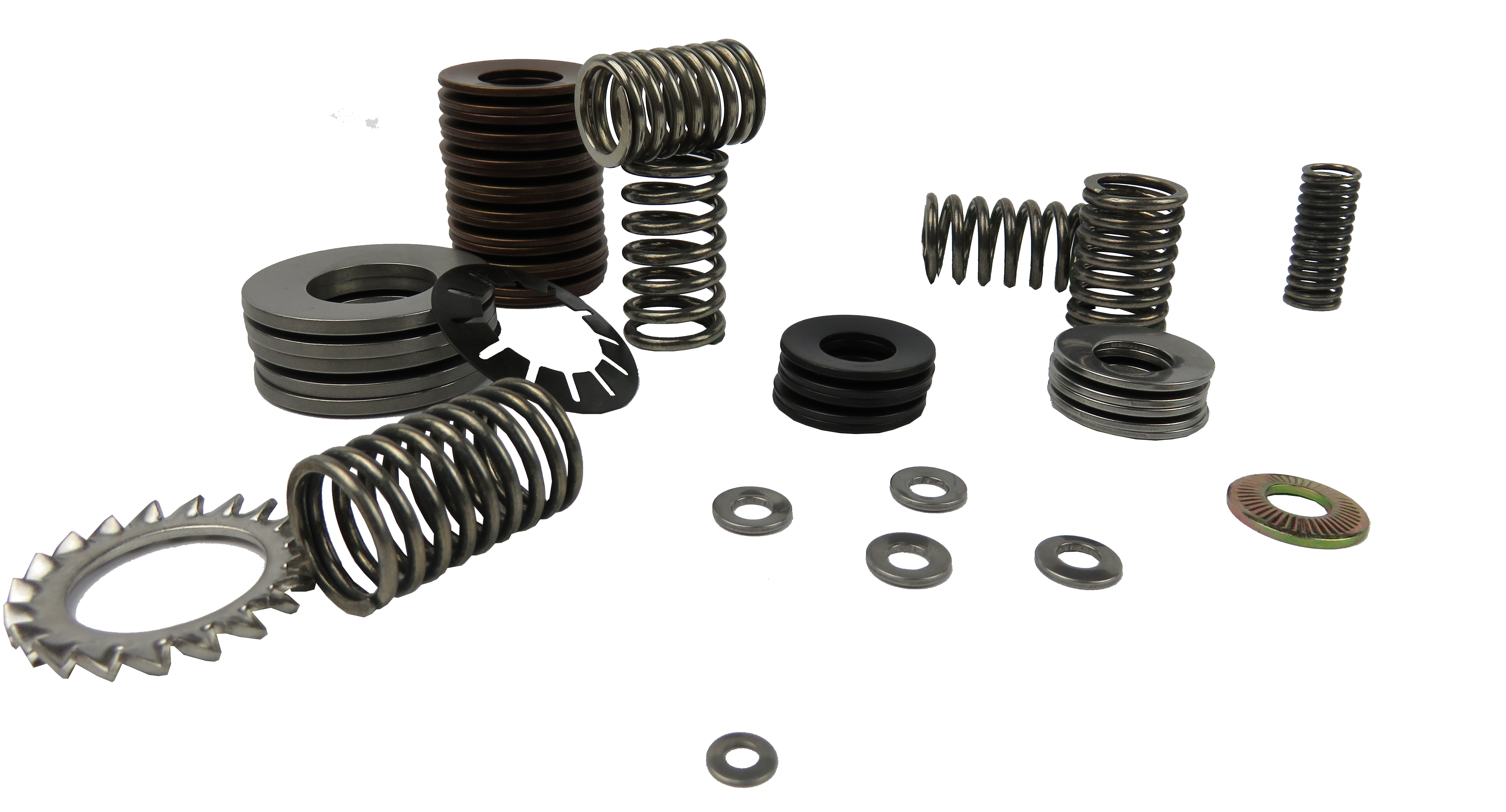

The most commonly used materials for butterfly springs are 50CrV4 and 60Si2MnA. Which of these two materials is more advantageous? Under normal circumstances, 50CrV4 and 60Si2MnA can be replaced with each other, but in certain cases, the material should be reasonably selected according to special requirements.

Next, we will detail the characteristics of 50CrV4 and 60Si2MnA:

60Si2MnA

Silicon (Si) exhibits remarkable solid solution strengthening capabilities, primarily functioning as a hardening agent in steel. By inhibiting the formation and growth of cementite nuclei during tempering processes, it alters the morphology and distribution of cementite particles, thereby enhancing steel's resistance to relaxation. Within appropriate ranges, higher silicon content significantly improves elastic relaxation resistance. However, silicon also tends to promote decarburization in steel.

Manganese (Mn) can enhance the hardenability of steel and has a certain effect of solid solution strengthening. However, when the manganese content is high, it will significantly increase the thermal sensitivity and temper embrittlement of the material, and at the same time, the tendency of cracking of the material in the quenching process will also increase accordingly.

50CrV4

Chromium (Cr) is an essential alloying element in spring steel, significantly enhancing its hardenability, oxidation resistance, and corrosion resistance while improving tempering stability and strengthening toughness. Adding 0.5% Cr to steel can increase yield strength by 16% and reduce decarburization layer depth by 50%. Furthermore, chromium effectively prevents graphitization during the spheroidizing annealing process of Si-Mn spring steel.

Vanadium (V), as a strong carbide forming element, forms VC in steel with fine dispersion and high hardness, which can refine the grain of steel, thus improving the plasticity, toughness and flexural strength ratio of steel.

Jiangsu Sunzo Elastic, with long-term experimental accumulation and extensive customer feedback, gives priority to 50CrV4 material in the manufacture of disc springs.