Views: 71 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

Optimization Of Manufacturing Process Of Wire-Drawn Disc Spring: From Precision Bending To Stable Tempering

In the core sectors of modern industry—from high-precision transmission in aerospace to powerful braking in new energy vehicles—disc springs play an indispensable role due to their compact structure, high load-bearing capacity, and excellent deformation recovery characteristics. As a leading enterprise in China's elastic component industry, Sunzo Spring has always been committed to driving product upgrades through technological innovation.

In specific application scenarios, disc springs require enhanced flexibility rather than high rigidity, with greater axial motion loads and lower force values. Conventional disc springs often fail to meet these requirements. While slotted disc springs can satisfy such needs, their manufacturing involves complex processes like stamping and heat treatment, resulting in low yield rates and significant waste, which complicates cost control. To address these technical challenges, we propose a manufacturing method for steel wire disc springs: repeatedly bending the wire into a disc-shaped ring through cold rolling, then welding the ends to form a complete butterfly spring. This approach effectively resolves the aforementioned technical issues.

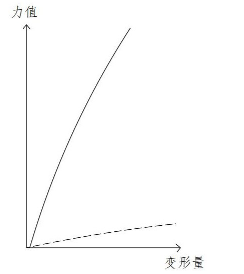

Figure 1 Comparison of force value curves of traditional disc spring and steel wire disc spring

-Force value curve of wire disc spring

—Force value curve of traditional disc spring

This paper will explore the manufacturing process of wire-drawn disc spring, and focus on the core process chain, i.e. from bending forming to low temperature tempering, and carry out a series of deep optimization and innovation measures.

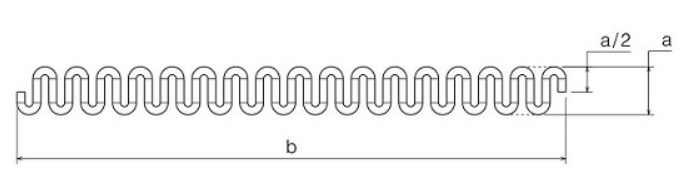

Figure 2 Schematic diagram of the structure of a wire disc spring

We have abandoned traditional single-mold designs and adopted digital simulation technology based on finite element analysis (FEA) to pre-calculate the wire's flow trajectory and stress concentration points during bending. The resulting high-precision progressive die ensures uniform stress distribution throughout the forming process, effectively reducing the risk of micro-cracks and stress concentration at the  source. Additionally, a dynamic pressure compensation system is implemented to dynamically adjust cold rolling parameters in real time, effectively offsetting fluctuations caused by minor material batch variations. This ensures that every wire disc spring achieves its initial shape to meet the high-precision standards specified in the design.

source. Additionally, a dynamic pressure compensation system is implemented to dynamically adjust cold rolling parameters in real time, effectively offsetting fluctuations caused by minor material batch variations. This ensures that every wire disc spring achieves its initial shape to meet the high-precision standards specified in the design.

Figure 3. Structure diagram of steel wire bent into rectangular surface

For different wire diameters and materials, we redefined the optimal R ratio (bending radius) for critical sections. By optimizing the R ratio, we significantly reduced the peak tensile stress on the outer side and the peak compressive stress on the inner side of the bend, resulting in a more uniform stress distribution across the cross-section and a substantial improvement in the spring's fatigue resistance.

After repeated bending forming and cold rolling, the complete steel wire disc spring is finally welded. There are complex and unstable processing stresses inside the spring, which is the main reason for the relaxation, deformation or early failure of the product in the following use. Therefore, the tempering treatment is not only a simple stress elimination, but also a key step to give the product stable performance.

We have abandoned the "one-size-fits-all" tempering approach. Through extensive experimental data, we established customized low-temperature tempering parameters for steel wire disc springs of various materials (e.g., piano steel wire, oil-quenched tempered steel wire) and wire diameters. By precisely controlling the tempering temperature (200°C) and holding time (1.6–2 hours), we effectively eliminate harmful stresses while preserving the material's essential elasticity and toughness, achieving an optimal balance between strength and toughness.

To prevent oxidation and decarburization on spring surfaces during tempering, we fully utilize controlled atmosphere protection tempering furnaces. This process ensures the purity of spring surface materials, prevents surface degradation from becoming a source of fatigue cracks, and thus guarantees the product's long-term stable service life and consistent mechanical properties.

Through systematic optimization of the core process chain of "bending and tempering", the steel wire disc spring has achieved a qualitative improvement:

1. Higher load accuracy: The load deviation rate is controlled within ±5%, meeting the strict requirements of high-precision assembly.

2. Superior anti-relaxation performance: Long-term load tests demonstrate significantly reduced load decay rates, extending service life by over 30%.

3. More stable performance: Maintains consistent elastic compensation capability under high-frequency vibrations and extreme temperature variations.

Expanded applicability: The optimized process enables our products to handle more demanding industrial applications with ease.

True craftsmanship shines in the finest details, and excellence is forged through meticulous craftsmanship. The in-depth exploration and refinement of two core processes—bending forming and low-temperature tempering—demonstrate Sunzo Spring Technology Co., Ltd.'s uncompromising commitment to product quality. We firmly believe that exceptional products stem from the ultimate refinement of every manufacturing step.

Choosing Sunzo means choosing lasting stability and reliability. We are committed to providing your products with critical resilience through advanced manufacturing processes and a rigorous quality system.