Views: 38 Author: Site Editor Publish Time: 2025-04-03 Origin: Site

Definition

A disc (butterfly) spring, commonly referred to as a disc spring, resembles a bottomless metal dish that can withstand axial loads. It is typically made from metal strips, sheets, or forgings and serves functions such as preloading and cushioning.

Characteristics of Disc Springs

In the direction of load application, they can bear a significant load with minimal deformation, meaning small deformation, large stiffness. Therefore, they can be used in scenarios with limited installation space.

They possess variable stiffness characteristics. Depending on different h0/t ratios, they can achieve properties that are approximately linear, decreasing, increasing, zero stiffness, or even negative stiffness.

Combination is free and convenient, allowing for standardized production, and ease of use, maintenance, and management.

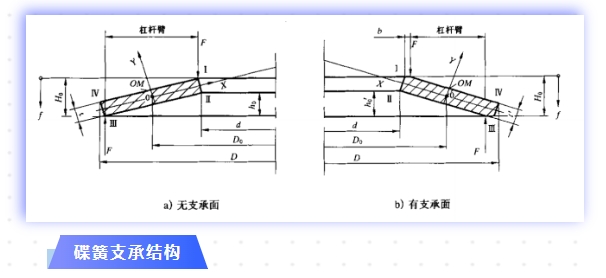

Structural Forms

Ordinary disc springs are divided into two types based on their support structures: with and without a support surface, as shown in Figure (1). Generally, disc springs with a thickness of ≥6mm will use a structure with a support surface.

Technical Requirements for Disc Springs

Materials are recommended to be 60Si2MnA or 50CrVA according to GB/T1972 standard (National Standard for Disc Springs), but stainless steel, heat-resistant steel, copper alloys, titanium alloys, nickel-based superalloys, or cobalt-based superalloys can be selected based on different service environments.

Limit deviations for size and position:

GB/T1972 classifies the size and load accuracy of disc springs into two levels of precision. Sizes include diameter (inner and outer), thickness, and free height.

Position tolerance: The national standard for disc springs does not explicitly require position tolerance, but the German standard DIN2093 specifies requirements for concentricity, such as D≤50 for 2.1T11; D>50 for 2.1T12.

Surface treatment, heat treatment, and stress relief processing all have clear requirements, as follows:

The surface should not have any burrs, cracks, or scratches that are harmful to use, whether it is oxidized or phosphated.

Disc springs requiring quenching and tempering should not exceed two quenching cycles, with hardness ranging from 42HRC to 52HRC.

The depth of the decarburized layer on one side for Class 1 disc springs should not exceed 5% of its thickness, and for Class 2 and 3 disc springs, it should not exceed 3% of their thickness (not exceeding 0.15mm).

Stress relief processing is a necessary procedure. The specific requirements are: compress the disc spring with a load of ≮2Ff=0.75h0, with a duration of ≮12 hours, or short-time compression, with a compression count of ≮5 times.

Special surface anti-corrosion treatment and strengthening treatment special technical requirements (such as fatigue, relaxation, creep, etc.) are agreed upon by both parties and are not mandatory national standards.

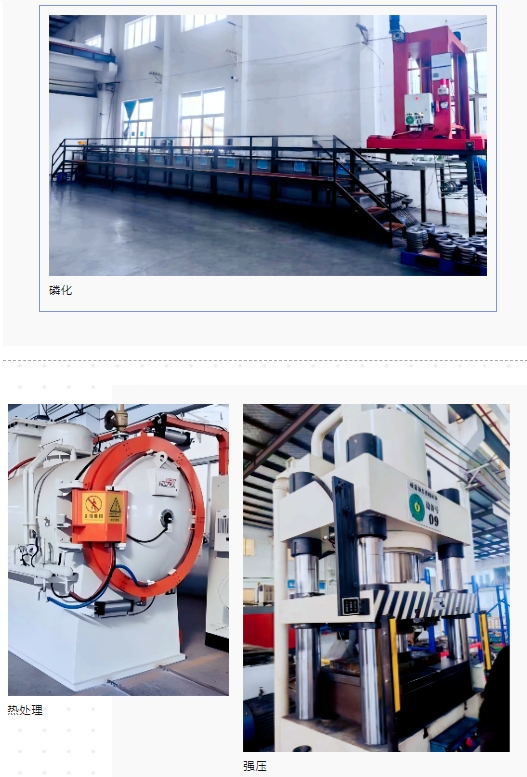

Disc Spring Manufacturing Processes:

Group I Thickness t≤1.25mm

Group II Thickness t between 1.25mm and 6mm

Group III Thickness t≥6mm

The production process flow for Group I is:

The production process flow for Group II is:

The production process flow for Group III is: